|

|

Watch this video to discover the features of the idonus UV-EXP Gen. 2 exposure systems.

|

Why LED technology?

Until recently, mercury arc lamps were the only sources capable of providing high intensity light

suitable for UV photolithography exposure. Thanks to the advances in LED technology, UV-LEDs have become

a very attractive alternative to the hazardous and energy-consuming mercury lamps.

Along with the ecological and security aspects, the technical advantages of UV-LEDs as compared with

traditional mercury lamps are numerous and significant for photolithography. A foremost advantage of

UV-LEDs is that they operate with consistent emission for very long lifetimes. As a result, daily

calibration and maintenance are not required. Furthermore, by being more energy efficient, LEDs have

reduced heating, which greatly simplifies system cooling.

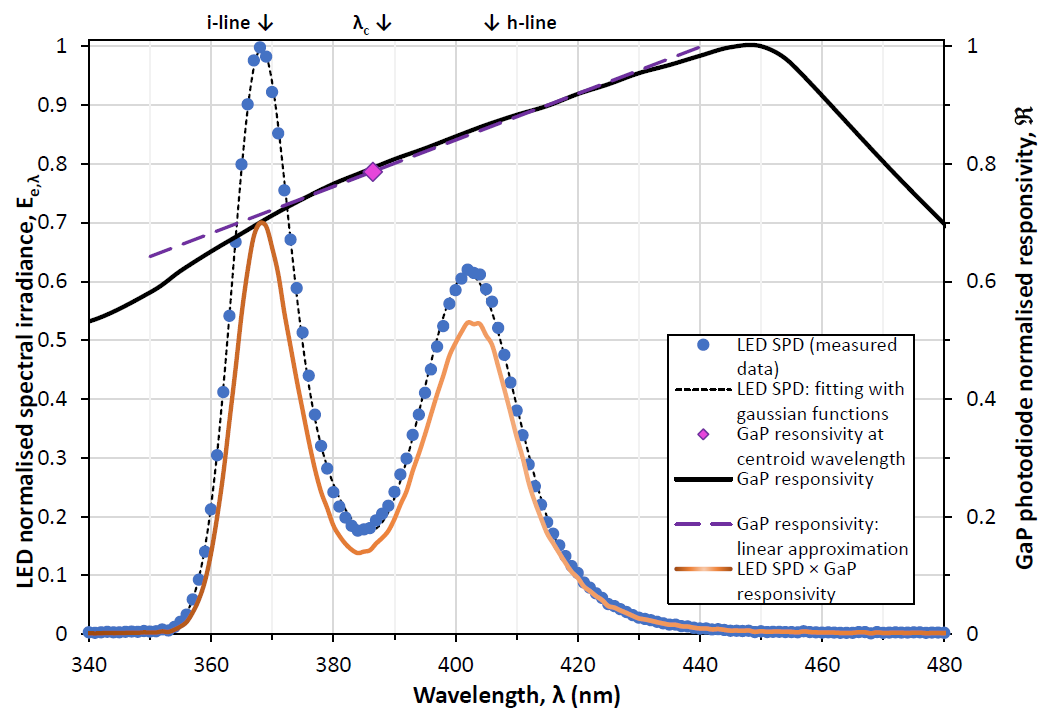

It is noteworthly that LEDs emitting at 365 nm, 405 nm and 435 nm (peak wavelengths) can be combined to mimic the

UV-A spectrum of mercury-arc lamps (i-line, h-line and g-line characteristic peaks of Hg element), as can be seen

in this graph.

Technical note:

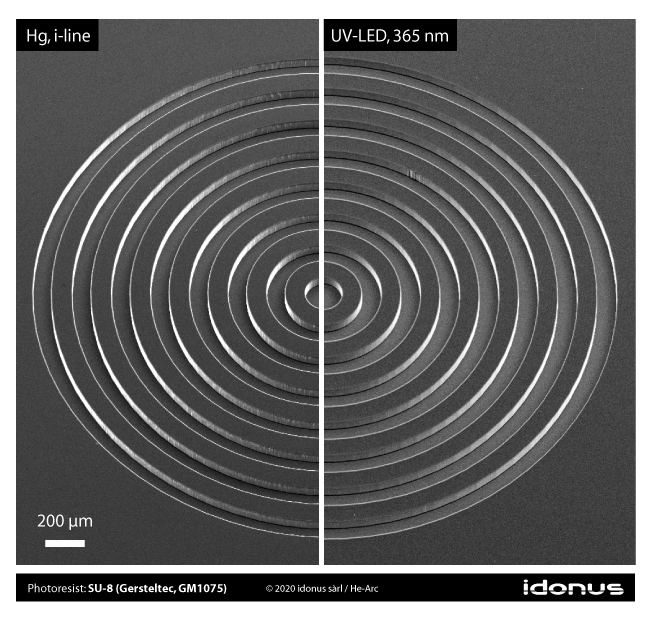

Photoresist exposure with the idonus

UV-EXP equipment (

PDF, preview).

Please, contact our

sales team to receive the full version of our technical note on

photoresist exposure.

White Paper: Human vision and the CIE chromaticity diagram (

PDF, preview paper).

Please, contact our

sales team to receive the full version of this White Paper.

Useful references

"Investigating the pattern transfer fidelity of

Norland Optical Adhesive 81 for nanogrooves by microtransfer molding,"

R. Sabahi-Kaviani and R. Luttge,

J. Vac. Sci. Technol. B 39, 062810 (2021).

DOI: 10.1116/6.0001333

"Gaining Micropattern Fidelity in an NOA81 Microsieve Laser Ablation Process,"

R. Sabahi-Kaviani and R. Luttge,

Micromachines, 2021, 12(1), 21.

DOI: 10.3390/mi12010021

.png)